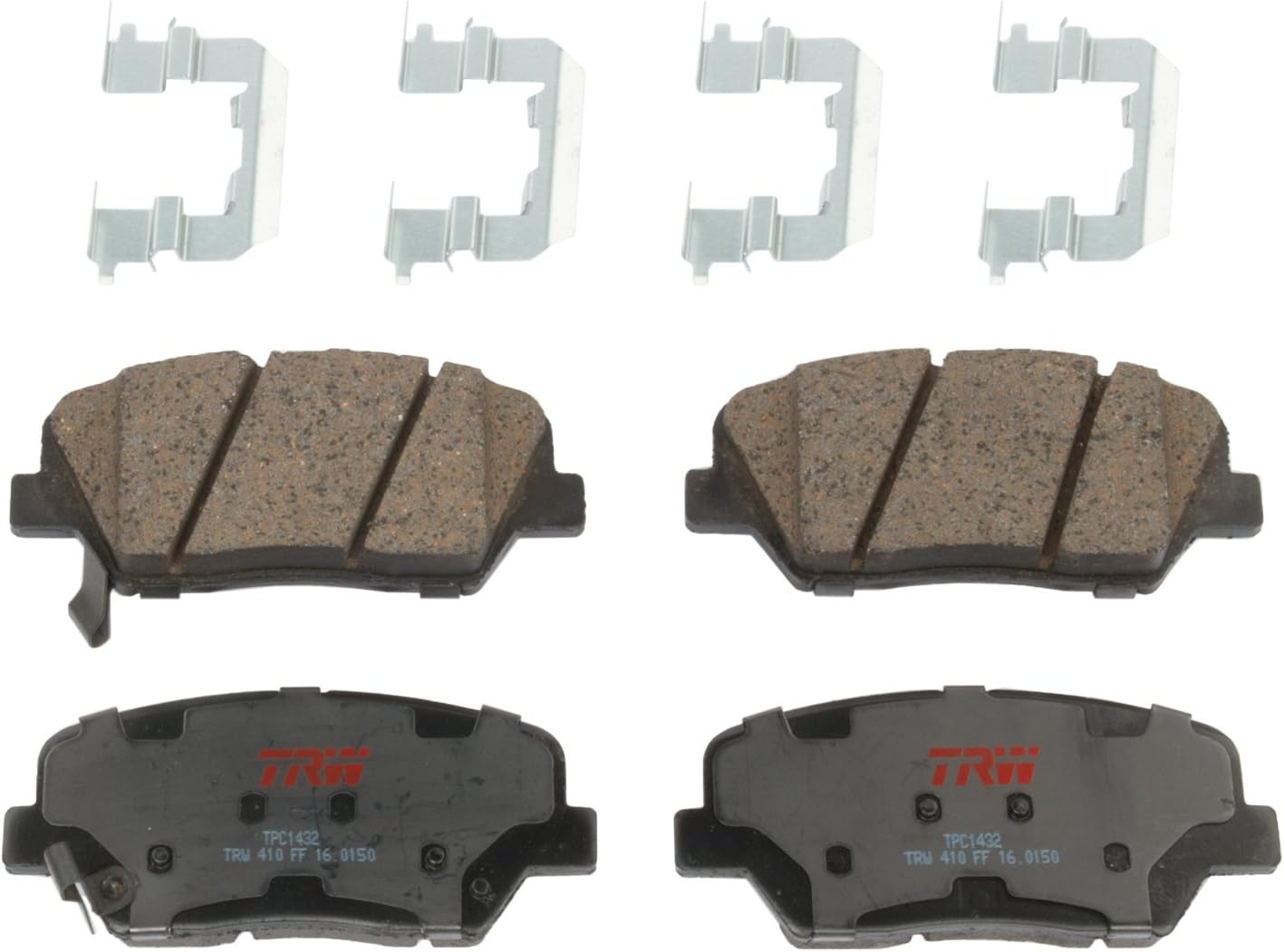

TRW Automotive TPC1432 Disc Brake Pad Set for Kia Sorento: 2011-2015 and other applications Front, black

$113.40 $98.61

- Optimum application specific friction material and formulation

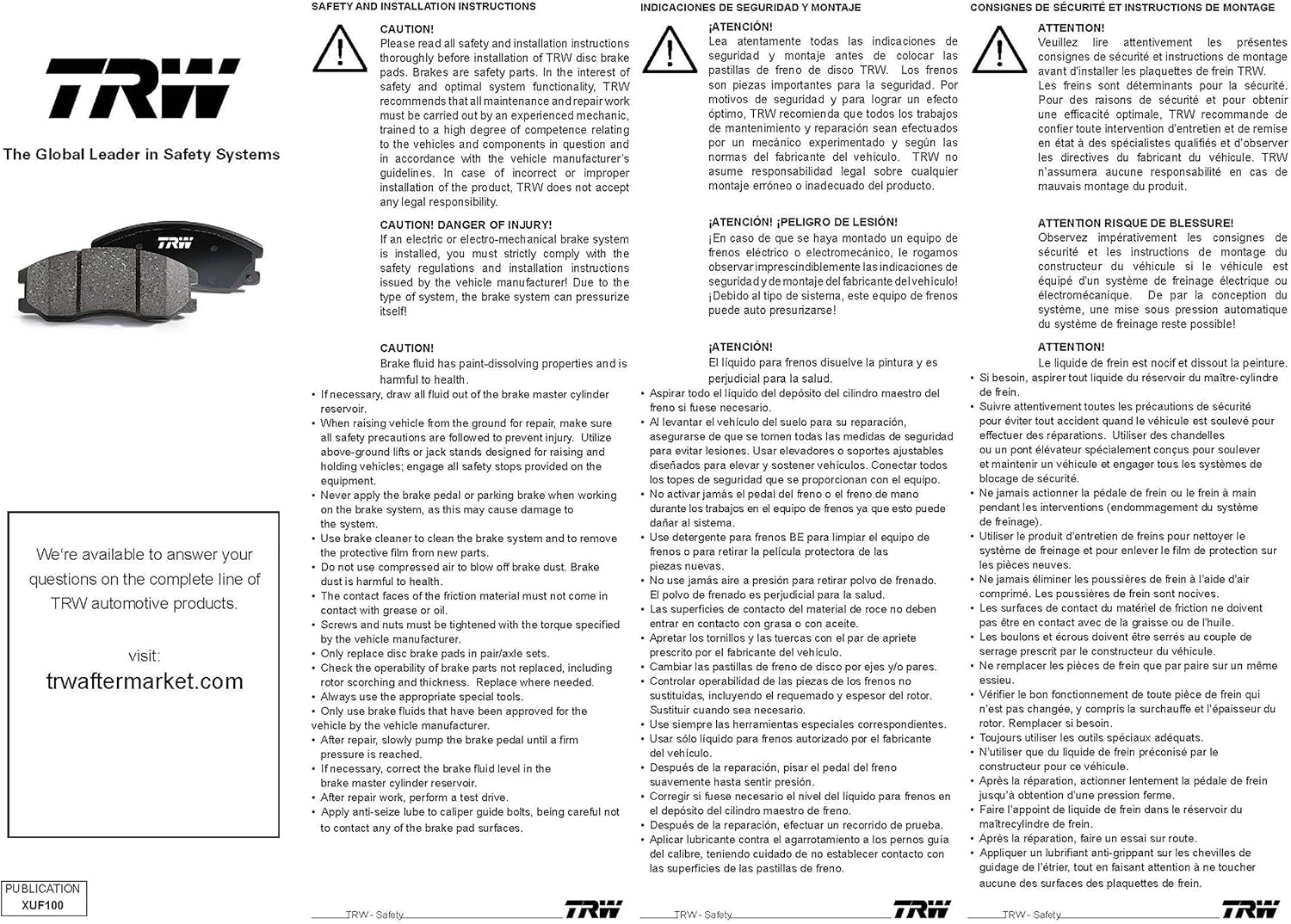

- All applicable hardware accessories included for a professional and safe installation

- TRW brake pads are slotted and chamfered for superior braking performance

- For confirmed fitment of this TRW Automotive Disc Brake Pad Set please verify your vehicle with the Amazon ‘Check Fit’ option

- Fits: Hyundai Azera: 2012 – 2017, Hyundai Santa Fe: 2010 – 2012, 2016, Hyundai Santa Fe Sport: 2013 – 2016, Kia Sorento: 2011 – 2015

TRW Ceramic Brake Pads

Choosing the right ceramic brake pads is a big decision – Choose TRW. Choose OE Design.

Choosing the right ceramic brake pads is a big decision. With more than 100 years’ experience, TRW is a pioneer in the development of braking system technologies and work closely with leading vehicle manufacturers. TRW engineers our brake pads to precise Original Equipment (OE) standards. We test the product to the extreme both in the lab and in real life, real road situations at every speed and on every terrain. In addition, our Ceramic Brake Pads deliver what we in the business call ‘fadeless performance’ to counteract the heat that braking in heavy traffic creates which could result in a lack of performance.

All TRW products are taken to market under the ‘Safety’ strapline. We never deviate from this and we never compromise because we believe that every stop could be that safety critical stop. We wouldn’t put our name to something that we wouldn’t fit in our own vehicles to transport our own families. All of this adds up to one fact: You can trust TRW to provide superior Ceramic Brake Pads to deliver the ultimate in braking experience.

|

|

|

|

|

|---|---|---|---|

PerformanceTRW brake pads undergo rigorous testing in order to meet or exceed OE specifications. By providing the optimum friction formulation for each make and model, you never have to choose between ceramic and semi-metallic. For fadeless performance, all TRW brake pads are tested at high temperatures. |

ComfortTRW provides a dominant offering of chamfered and slotted brake pads, plus the greatest number of SKUs with noise-reducing hardware. TRW applies bonded Nitrile rubber-coated steel shims on all pads for noise-free braking. Slots prevent water, dirt and dust build up on the friction surface giving more efficient contact and reducing noise. |

AccessoriesFor a safe and easy pad change all TRW brake pads are supplied with comprehensive fitting instructions; the largest range of installation hardware and grease. |

CITECTRW disc brake pads are coated with Citec. Citec “Coating Innovation Technology” was developed in house by TRW and reduces the braking distance traveled in the first stops after a pad change. This advanced silicate coating is applied to the friction material of replacement brake pads, resulting in an improved contact between the brake disc and pad. |

Engineered with confidence – performance focused

Tried and true

TRW brake pads undergo a rigorous set of tests, both during the production process and on the road. TRW Aftermarket mirrors the testing procedures used by OE engineers, and a wide range of additional tests to ensure the complete safety of our pads.

The perfect fit, every time

TRW’s friction program offers products for 98% of all vehicles on the road in North America; both imports and domestic. We are committed to being first-to-market with new vehicle applications. We support this with accurate and comprehensive electronic catalogs, making it easy to identify the correct part number quickly.

- We mirror OE formulation removing any confusion over which formulation to choose.

- TRW applies ‘bonded Nitrile rubber-coated steel shims to all its Ceramic Brake Pads.

- Intelligent design includes slots & chamfers which create a more effective contact & reduce noise.

- All necessary accessories provided: hardware, grease & instructions, for a safe & easy job.

- TRW offers products for 98% of all vehicles on the road in North America.

Product information |

|||||||||||||||||||||||||||||||||||

|

| Weight | 4.10 lbs |

|---|

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.